Kunshan SGT Equipment Industry Co.,Ltd备案号:苏ICP备08101050号-1

Tel:+86-512-57238808 008613809068099

Mail:sj.fu@sgtplast.cnWechat:18379159914

Address:No.7, Changyang Road, Yanqiaobang, High Tech Zone, Kunshan City, Jiangsu Province

Hotline

+86-512-57238808 008613809068099

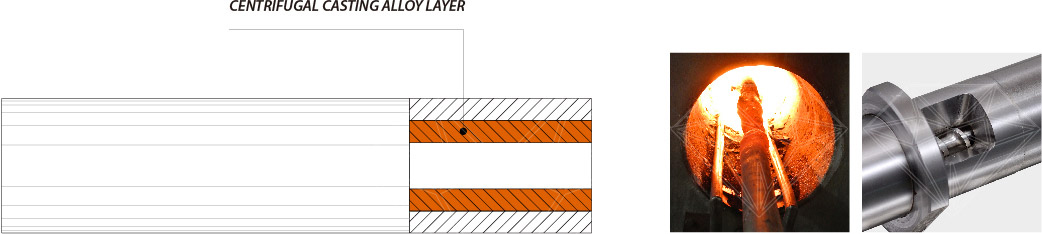

The centrifugally cast alloy material tube is formed by centrifugally casting a NiCrBSi or CrFe alloy powder in a steel outer casing at a high temperature. The outer casing structure of the material pipe is pearlite or martensite, and the inner surface of the material pipe is martensite or martensite plus carbide. The tube has high strength, toughness, surface hardness and corrosion resistance. Suitable for high-wear and high-corrosion environmental tubes, widely used in injection molding of PC, PE, PA, PS, PMMA, ABS, PVC, PSU, POM.

+86-512-57238808

| Product Code |

Material |

Organization |

Hardness |

Wear resistance |

Corrosion resistance |

Resilience |

Service life |

Applicable occasions |

Recommended application |

|---|---|---|---|---|---|---|---|---|---|

|

SGT-B-Ⅱ |

The base material is quenched and tempered by medium-low carbon aluminum or chromium-containing low alloy steel, and the inner surface is metallurgical iron-based wear layer |

The material tube is tempered sorbite and the inner surface layer is martensite plus carbide structure. |

Hardness HRC54-60 |

★ ★ ★ |

★ ★ ★ |

★ ★ ★ |

★ ★ ★ |

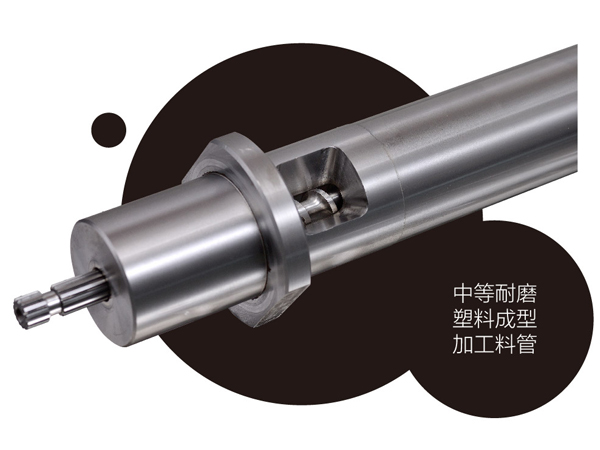

Medium wear-resistant plastic forming processing tube |

PC, PE, PP, PA, PPO, PAR, PPS, PMMA, ABS, PSU, PVC, POM, etc |

|

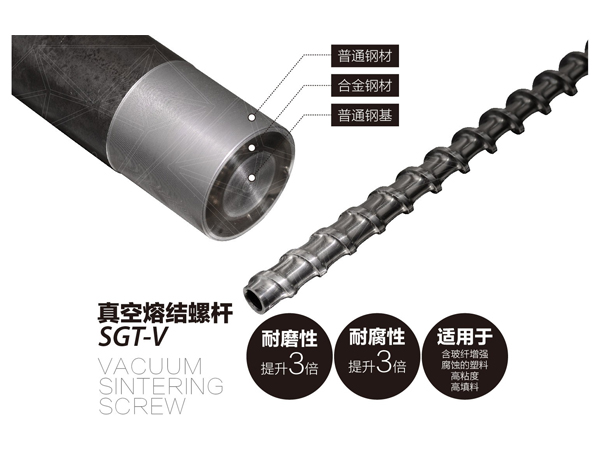

SGT-B-Ⅲ |

The base material is quenched and tempered for medium and low carbon low alloy steel, and the inner surface is metallurgical nickel base wear resistant alloy. |

The material tube is tempered sorbite and the inner surface layer is martensite plus carbide |

Barrel base HRC38-45, inner surface HRC55-62 |

★ ★ ★ ★ |

★ ★ ★ ★ |

★ ★ ★ |

★ ★ ★ ★ |

High viscosity, high filler, glass-reinforced and corroded plastic forming tube |

Forming machine tubes for PC, PE, PP, PA, PPO, PAR, PPS, PMMA, ABS, PSU, PVC, POM, etc. |

Kunshan SGT Equipment Industry Co.,Ltd备案号:苏ICP备08101050号-1

Tel:+86-512-57238808 008613809068099

Mail:sj.fu@sgtplast.cnWechat:18379159914

Address:No.7, Changyang Road, Yanqiaobang, High Tech Zone, Kunshan City, Jiangsu Province